Making a Mackintosh

Mackintosh’s signature rubberised coats continue to be made by skilled craftsmen in our factory using the same tradition pioneered in the early 19th century. Each coat is made entirely by hand and one artisan works on a single garment from start to finish.

Fabric

The core material in a classic Mackintosh coat is the bonded cotton fabric - two layers of cotton bonded together with rubber that is dyed to perfectly match the outer cotton layers so there is no show-through.

Pattern layout and marking

Once the bonded cotton arrives at the Mackintosh factory the patterns are laid out and marked up.

Cutting

The bonded cotton fabric is then cut making each individual piece ready for them to be sewn and glued together.

Gluing

Once the pieces of a coat have been cut into the correct patterns, they are sewn, sealed and lapped using a special type of rubber solution that is applied by finger, an intricate technique that is learnt and mastered over many years. As well as ensuring that the seams of each coat are waterproof, this technique also makes it easier to join both curved edges and corners.

Pressing & taping

Once each seam is glued they are pressed to ensure the bond is strong; this guarantees the seam will be durable and long lasting. When the solution on the coat is dry, any excess is removed by roller and brush A water-resistant tape is then attached by hand and pressed over any exposed seams to make sure there is no water intrusion resulting in a 100% waterproof garment.

Finishing

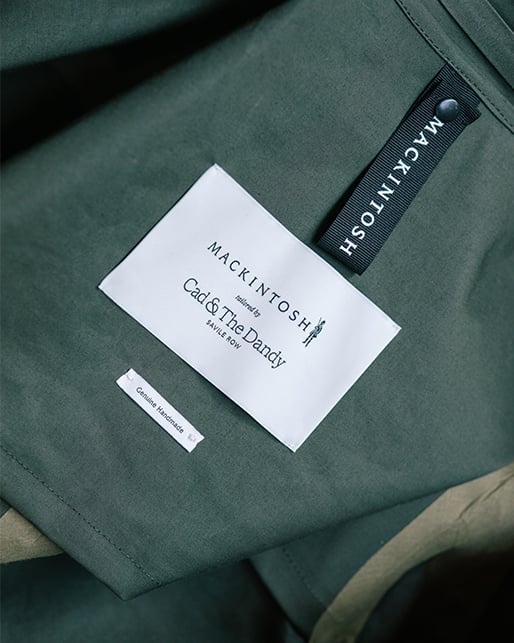

Lastly, finishing touches such as the airing eyelets are punched in, and buttons sewn on.

The intricate and labour-intensive production process results in a very limited number of garments being produced each year making sure the quality is of the highest standard.